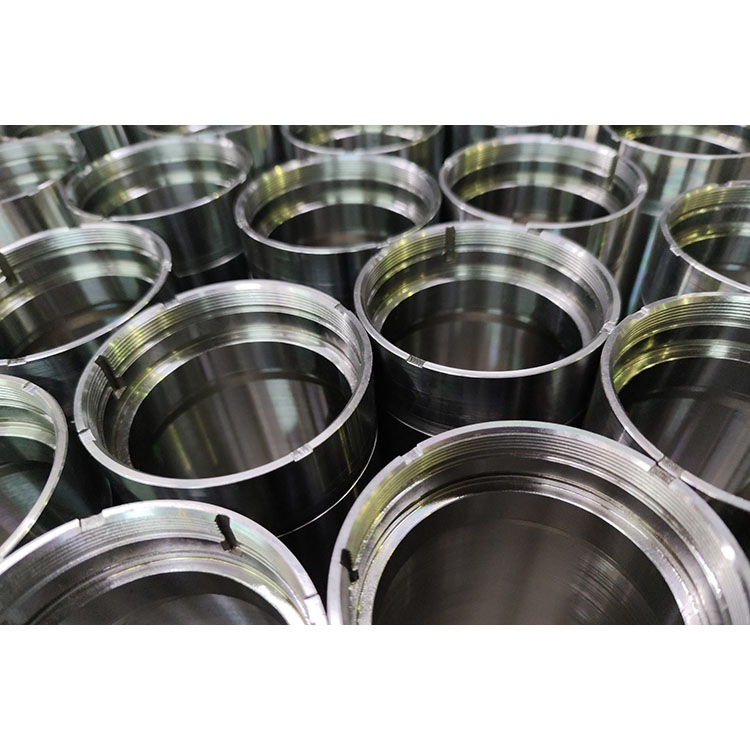

China Cast Iron Motor Housing by Casting Manufacturers, Suppliers, Factory

Our pursuit and corporation intention is to "Always satisfy our client requirements". We continue to develop and style remarkable high-quality items for each our outdated and new shoppers and accomplish a win-win prospect for our customers likewise as us for Cast Iron Motor Housing by Casting,High Precision CNC Mobile Phone Metal Housing, Welcome to setup long-term romantic relationship with us. Best Value Permanently Top quality in China.

Cast Iron Motor Housing by Casting, Our company is an international supplier on this kind of merchandise. We present an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful solutions while providing value and excellent service. Our mission is simple: To offer the best solutions and service to our customers at the lowest prices possible.

Hot Products

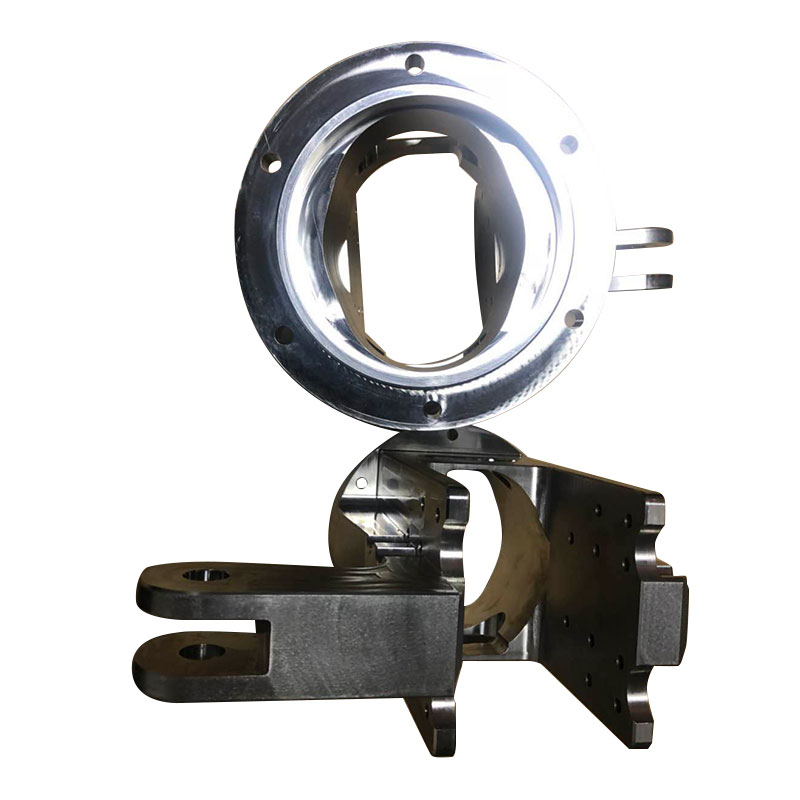

Medical Device Fixture CNC Machining

The following is about Medical Device Fixture CNC Machining.2021 New Design Red Anodizing Aluminum CNC Machining Service

2021 New Design Red Anodizing Aluminum CNC Machining Service, Aluminum CNC parts are the all-time preferred auto components for auto spares and other industries, not just because they are very lightweight and attractive, but also because aluminum has many additional properties like its durability and its ease of installation. Under specific conditions, aluminum can be made very corrosion resistant. The fact that this metal can be cheaply obtained makes it the most economical option for the manufacturing industry. Aluminum parts anodizing is a process that makes aluminum the ultimate metal for a lot of interior and exterior building purposes and designs. Aluminum can also be molded into different shapes to form various aluminum parts.Highest Level Military Parts Cnc Machining

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.High Demand Aerospace Parts CNC Machining

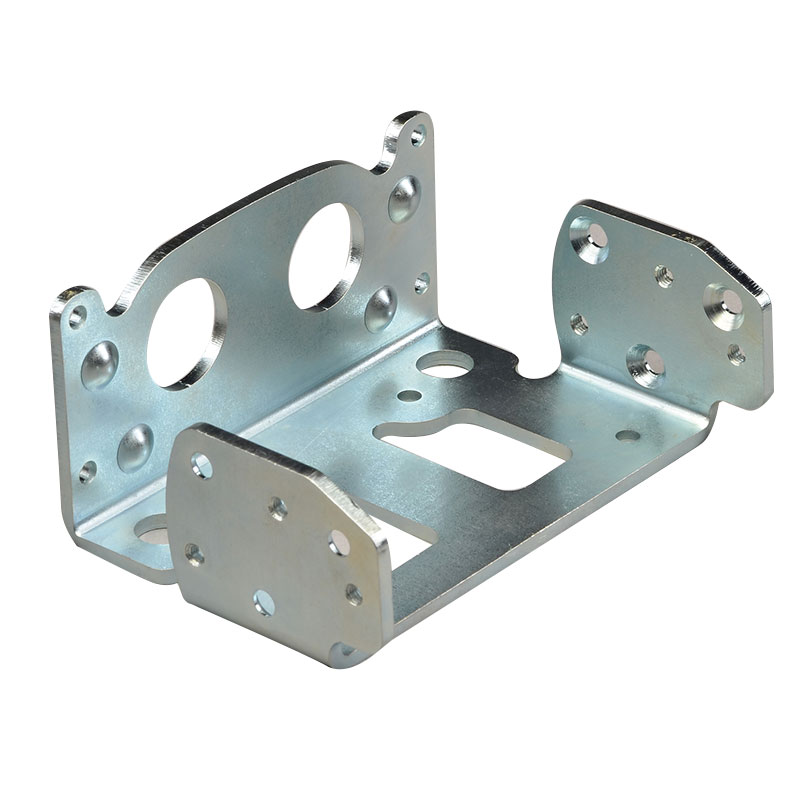

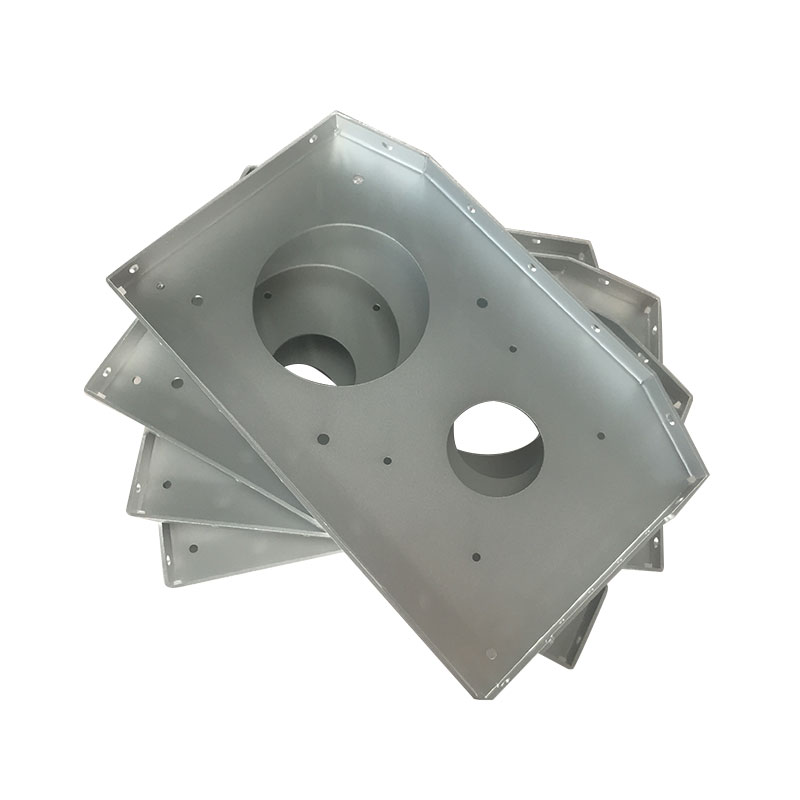

Aluminum alloy high demand aerospace parts CNC Machining has a widely application in many industries, as Aluminum is one of the most commonly used metals which is durable, lightweight, malleable, low cost, and recyclability.Aluminum Sheet Metal Bending Stamping Fabrication

High quality Aluminum Sheet Metal Bending Stamping Fabrication made in China. Guoye Optoelectronics is Aluminum Sheet Metal Bending Stamping Fabrication manufacturer and supplier in China.