China Mechanical Connectors Products CNC Turning Manufacturers, Suppliers, Factory

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Mechanical Connectors Products CNC Turning,Mechanical Connectors Components CNC Turning, We sincerely welcome buddies to negotiate business enterprise and start cooperation with us. We hope to join hands with good friends in different industries to produce a brilliant long term.

Mechanical Connectors Products CNC Turning, Relying on superior quality and excellent post-sales, our items sell well in America, Europe, the Middle East and South Africa. We're also the appointed OEM factory for several worlds' famous merchandise brands. Welcome to contact us for further negotiation and cooperation.

Hot Products

Auto Transmission Parts CNC Turning

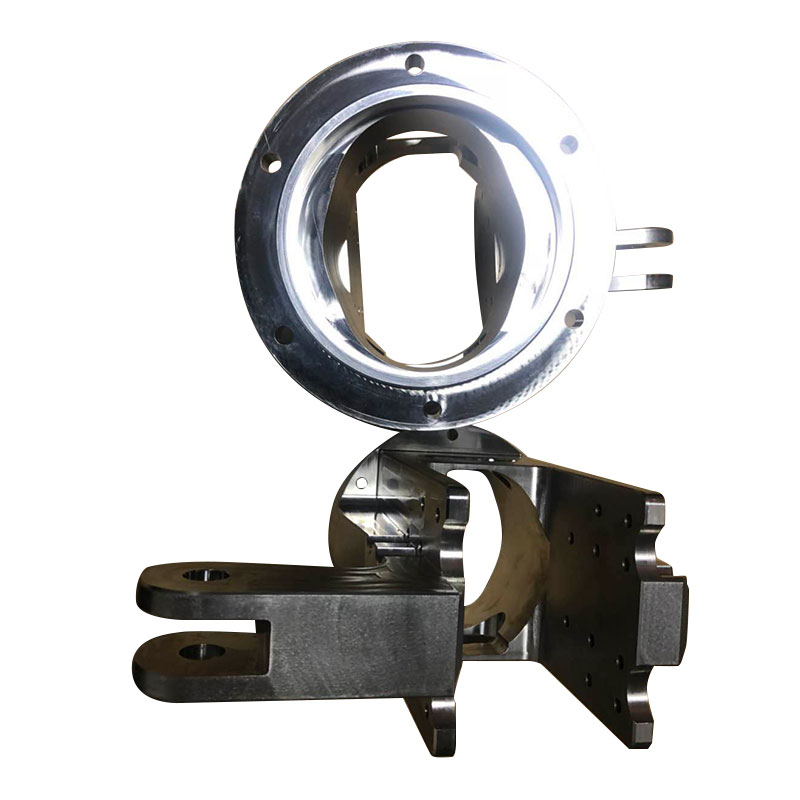

The following is about Auto Transmission Parts CNC Turning.Metal Precision Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.Smart Mechanical Parts Vacuum Casting

Vacuum casting services is a type of rapid prototyping technology. It is used for producing a photocopy of the original product in a vacuum state, and then use (PU, transparent PU, POM-like, ABS) and other materials to cast the same copy as the product prototype.

Vacuum casting services are suitable for the customer who requires several sets of rapid prototype parts, which significantly reduces the cost and development time. The following is about Smart Mechanical Parts Vacuum Casting.Servo Motor Shaft Aerospace Parts CNC Turning

Servo Motor Shaft is one of the important parts of the motor. It acts as a link between the electromechanical energy conversion between the motor and the device, supporting the rotating parts, transmitting torque and determining the relative position of the rotating parts to the stator.The following is about Servo Motor Shaft Aerospace Parts CNC Turning.Sheet Metal Stamping Precision Stamping Parts

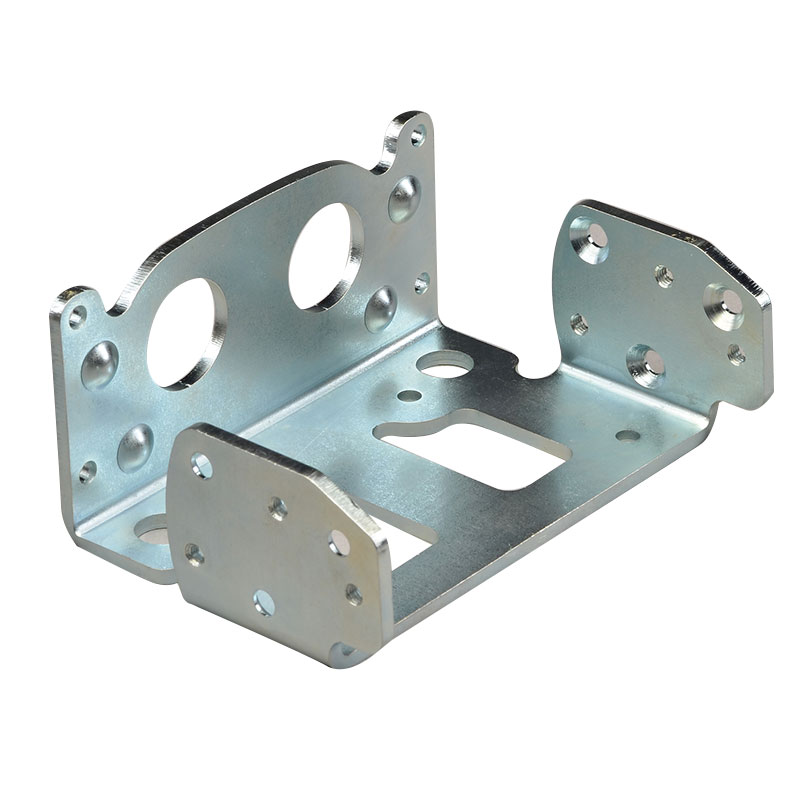

Hot sale quality Sheet Metal Stamping Precision Stamping Parts with Low Price made in China. Guoye Optoelectronics is Sheet Metal Stamping Precision Stamping Parts manufacturer and supplier in China.Metal Aerospace Parts CNC Machining

A leader in manufacturing complex details and components for the aerospace industry, shbury provides metal aerospace parts CNC machining. Several in-house processes, including precision CNC turning, CNC milling, lapping and OD grinding are incorporated to fabricate the cnc parts. We also perform in-house deburring and dot peen marking. Outside services sourced to our vendor base include heat treatment and a tungsten carbide plasma spray coating. Tolerance requirements are held to +-0.01mm, a circular run out of +-0.005mm. , Dimensional inspection as well as NDT inspection was done in-house.