China Motorcycles Components CNC Machining Manufacturers, Suppliers, Factory

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Motorcycles Components CNC Machining,Motorcycles Parts CNC Milling,Motorcycles Products CNC Machining,CNC Machining Aluminum Parts CNC Machining,Magnesium CNC Machining Parts, We have been also the appointed OEM factory for several worlds' famous merchandise brands. Welcome to speak to us for more negotiation and cooperation.

Motorcycles Components CNC Machining, We pay high attention to customer service, and cherish every customer. Now we have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Hot Products

Medical Infusion Pump Housing Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Infusion Pump Housing Rapid Prototypes.2021 New Design Red Anodizing Aluminum CNC Machining Service

2021 New Design Red Anodizing Aluminum CNC Machining Service, Aluminum CNC parts are the all-time preferred auto components for auto spares and other industries, not just because they are very lightweight and attractive, but also because aluminum has many additional properties like its durability and its ease of installation. Under specific conditions, aluminum can be made very corrosion resistant. The fact that this metal can be cheaply obtained makes it the most economical option for the manufacturing industry. Aluminum parts anodizing is a process that makes aluminum the ultimate metal for a lot of interior and exterior building purposes and designs. Aluminum can also be molded into different shapes to form various aluminum parts.Office Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.CNC Machining 4 axis Aluminium Anodizing Parts

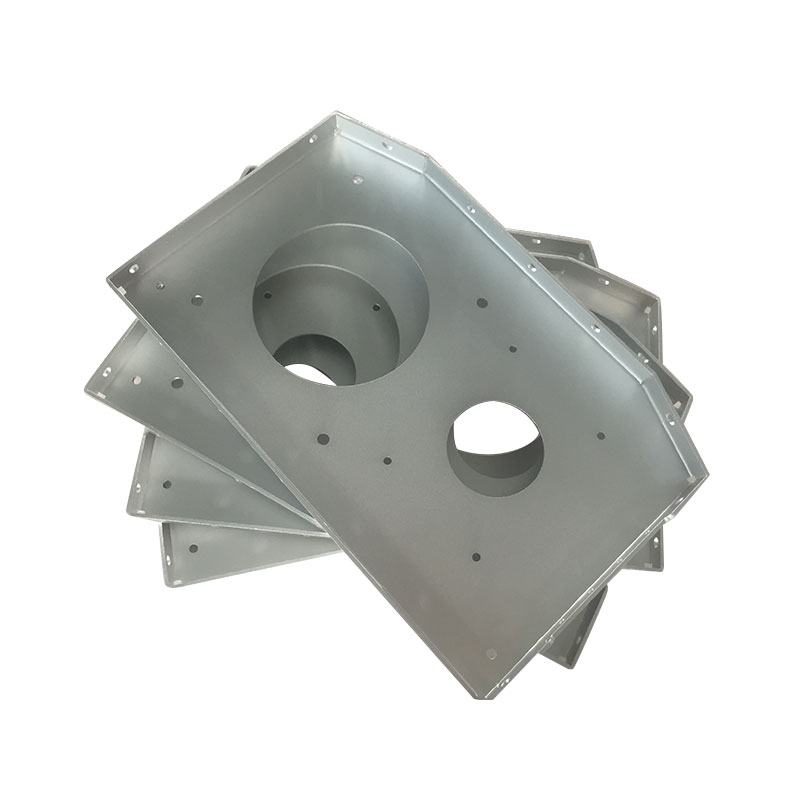

CNC Machining 4 axis Aluminium Anodizing Parts:we are specialized manufacturers from China, Aluminum Block, Cnc Milling Machining Parts suppliers/factory, wholesale high-quality products of Aluminum Cnc Machining Parts R & D and manufacturing, we have the perfect after-sales service and technical support. Look forward to your cooperation!Motorcycles Parts CNC Machining

CNC machines are indispensable for motorcycles simply for the fact that you can create bike parts. People should know that these machines easily create bike parts, which are easily damaged during accidents making them easier to replace. Oftentimes during light crashes, bike parts can be damaged, scratched, crushed, or even brushed against the pavement and in need of replacements.

If you have a damaged bike part and need of a replacement, a CNC Machining motorcycles spare parts would be the desired way to go about it.The following is about motorcycles parts CNC machining.Motor Shafts Parts CNC Turning

The following is about Motor Shafts Parts CNC Turning.