China Stainless Steel Sheet Bending Stamping Parts Manufacturers, Suppliers, Factory

We now have quite a few superb workers customers very good at marketing and advertising, QC, and working with forms of troublesome dilemma while in the creation approach for Stainless Steel Sheet Bending Stamping Parts,Galvanized Sheet Bending Parts,Galvanized Metal Bending Parts and Galvanized Sheet Metal,Metal Sheet Forming Steel Bending Parts Bending Steel Plate,Galvanized Sheet Bending Equipment Metal Parts Sheet Metal, We aim at Ongoing system innovation, management innovation, elite innovation and market innovation, give full play to the overall advantages, and constantly improve service quality.

Stainless Steel Sheet Bending Stamping Parts, Our goods are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have now got high praise by partner. We're looking forward to establishing business relationship with you.

Hot Products

Medical Infusion Pump Housing Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Infusion Pump Housing Rapid Prototypes.Silicone Buttons Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal. But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about silicone buttons products vacuum casting.Medical ECG Device Shell CNC Machining

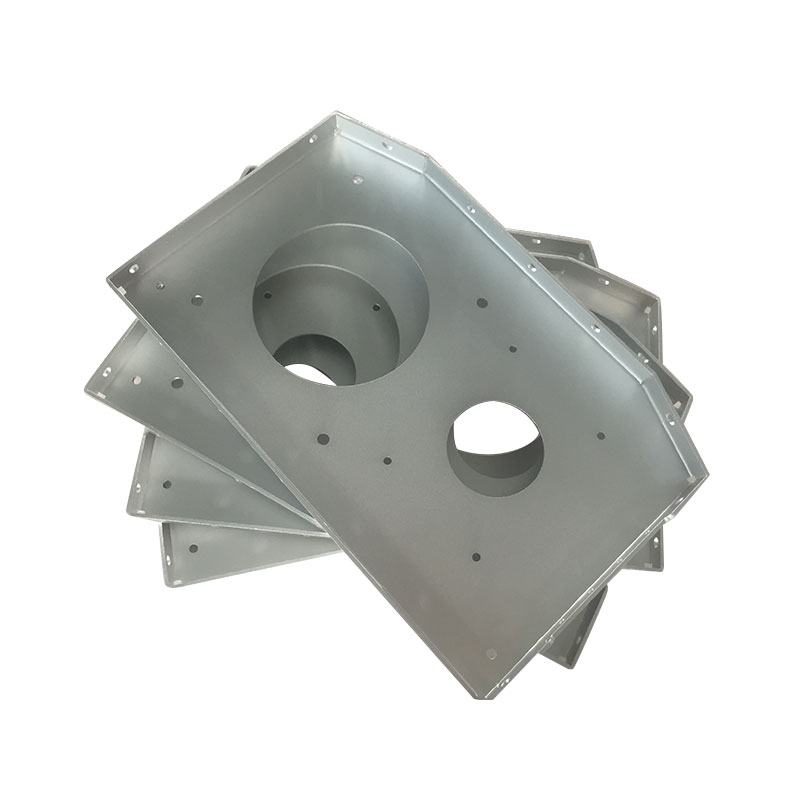

The following is about Medical ECG Device Shell CNC Machining.Galvanized Steel Sheet Metal Bending Parts

Galvanized steel sheet metal bending parts or galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.Auto Waterproof Rubber Parts Vacuum Casting

We frequently vacuum cast rubber auto waterproof parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre (Shore 30 – 95A hardness) The level of detail matches that of an injection moulded part.The following is about Auto Waterproof Rubber Parts Vacuum Casting.