China Sheet Metal Stamping Parts Manufacturers, Suppliers, Factory

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Sheet Metal Stamping Parts,Sheet Stamping Small Metal Parts,Metal Stamping Sheet Metal Parts,Metal Sheet Aluminum Stamping Parts,Best Stamping Sheet Metal Stamping Parts, Welcoming interested companies to cooperate with us, we look forward to having the opportunity of working with companies around the world for joint growth and mutual success.

Sheet Metal Stamping Parts, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

Hot Products

2021 New Design Red Anodizing Aluminum CNC Machining Service

2021 New Design Red Anodizing Aluminum CNC Machining Service, Aluminum CNC parts are the all-time preferred auto components for auto spares and other industries, not just because they are very lightweight and attractive, but also because aluminum has many additional properties like its durability and its ease of installation. Under specific conditions, aluminum can be made very corrosion resistant. The fact that this metal can be cheaply obtained makes it the most economical option for the manufacturing industry. Aluminum parts anodizing is a process that makes aluminum the ultimate metal for a lot of interior and exterior building purposes and designs. Aluminum can also be molded into different shapes to form various aluminum parts.Mechanical Liquid Urethane Resin Parts Vacuum Casting

Vacuum casting services is a type of rapid prototyping technology. It is used for producing a photocopy of the original product in a vacuum state, and then use (PU, transparent PU, POM-like, ABS) and other materials to cast the same copy as the product prototype.

Vacuum casting services are suitable for the customer who requires several sets of rapid prototype parts, which significantly reduces the cost and development time.The following is about Mechanical Liquid Urethane Resin Parts Vacuum Casting.Car Engine Housing Parts CNC Machining

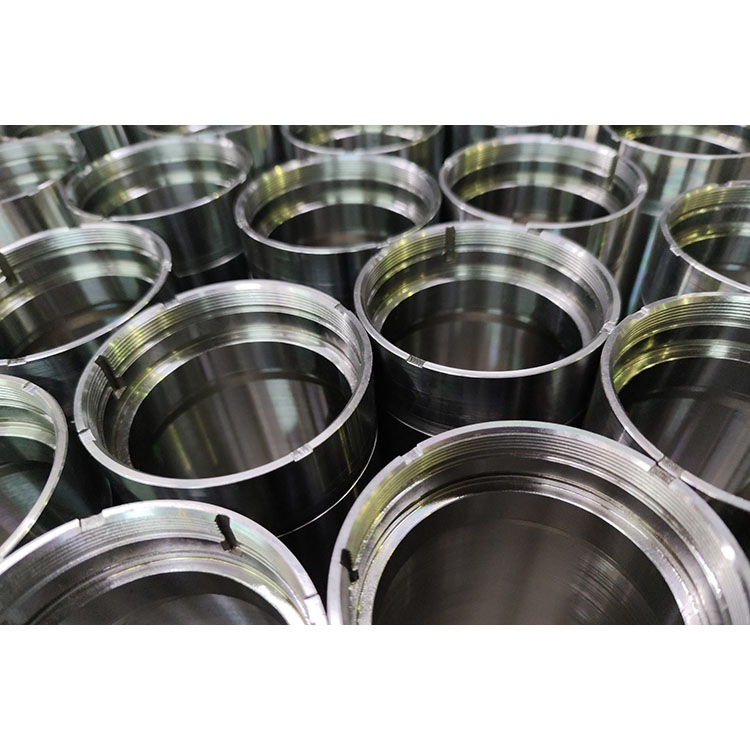

For some automotive components, CNC machining, which involves carrying out tasks like drilling and boring with computer control and automation, now serves as a favourable option for both prototyping and production.

CNC machines turn a digital file into a sequence computer instruction, which are sent to a motorised tool such as a drill, lathe or mill. The tool turns a block of material into a finished product by cutting it in the appropriate places, providing much greater accuracy than conventional machining.The following is about car engine housing parts CNC machining.Cold Carbon Steel Sheet Metal Parts

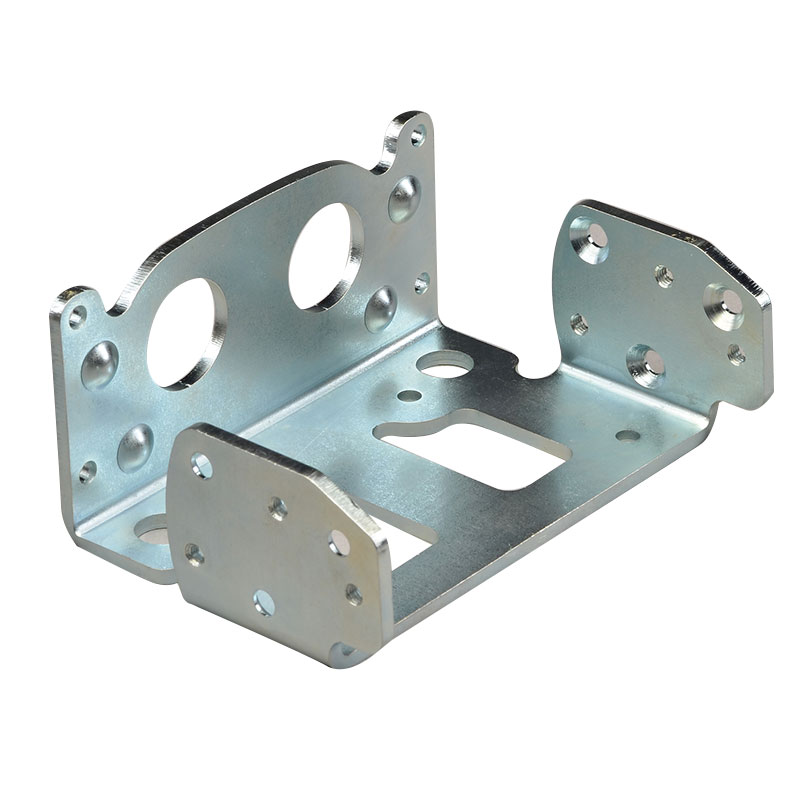

Cold Carbon Steel Sheet Metal PartsAuto Sensor Housing Parts CNC Machining

Because of the characteristics of high precision, high speed, high efficiency and safety and reliability, CNC turning parts are more and more widely used in equipment manufacturing industry, especially the automotive parts, which combines the latest technologies of automation, computer and measurement, and uses a variety of sensors to make it more flexible, versatile, reliable and easy to use and maintain.

The best Auto Sensor Housing Parts CNC Machining supplier ShenZhen Shbury technology Co.,Ltd provides custom CNC machined sensor housing parts. We are a popular manufacturer of all types of sensor housing made by high-quality precision CNC machining processing, especially the temperature sensor housing and pressure sensor housing.Military Parts Dowel Pins CNC Turning

We carefully consider the dowel pins material to be used as well as the dowel destination. We take into account the ductility of the destination hole and the ductility of the dowel pins material being used to manufacture the machined parts with accurate dimensions. Regarding size and precision, Alpha Omega Swiss manufactures precision dowel pins to exacting tolerances. We can produce dowel pins to a tolerance of +/- .0001 utilizing stainless steel, tool steel, brass, or aluminum.The following is about Military Parts Dowel Pins CNC Turning.