China Sheet Metal Stamping Parts Manufacturers, Suppliers, Factory

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Sheet Metal Stamping Parts,Sheet Stamping Small Metal Parts,Metal Stamping Sheet Metal Parts,Metal Sheet Aluminum Stamping Parts,Best Stamping Sheet Metal Stamping Parts, Welcoming interested companies to cooperate with us, we look forward to having the opportunity of working with companies around the world for joint growth and mutual success.

Sheet Metal Stamping Parts, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

Hot Products

Electronic Hookah Nozzle Products CNC Turning

The following is about Electronic Hookah Nozzle Products CNC Turning.Auto O Right Silicone Parts Vacuum Casting

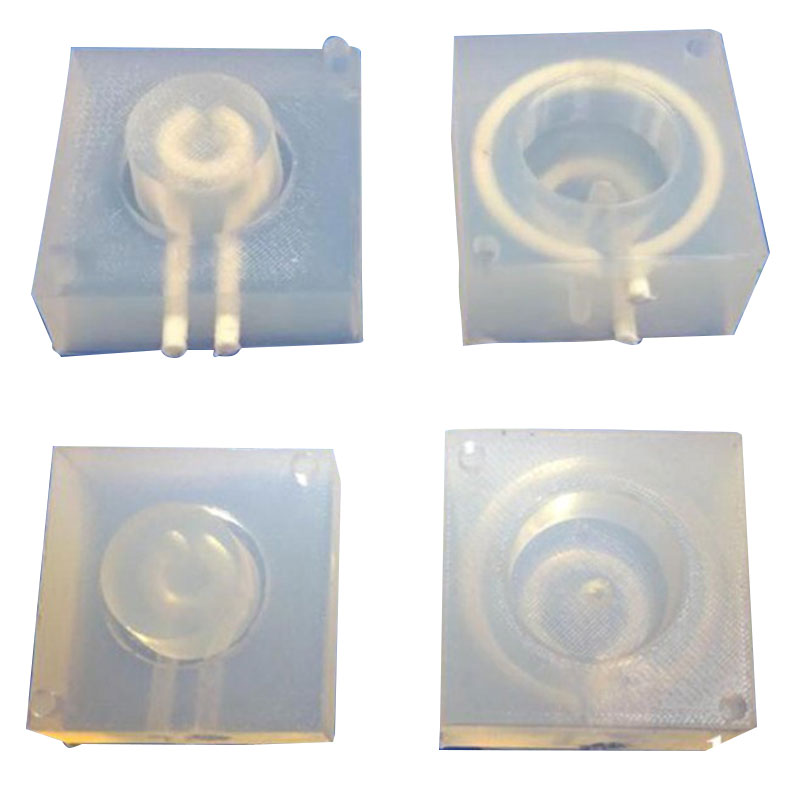

The original model for vacuum casting is generally created using the stereolithography method. From this model, a primary mold of silicone is created and filled in the vacuum chamber with liquid polyurethane casting resin (PUR). The vacuum prevents bubbles and shrink holes even in complex molded parts. After hardening, the service of the casting is finished. Given the numerous available polyurethanes and ureols (PU hard foam), many conventional production plastics (injection molding) can be simulated.The following is about Auto O Right Silicone Parts Vacuum Casting.Auto Oil And Gas Rubber Parts Vacuum Casting

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.Precision Machined Sheet Bending Parts

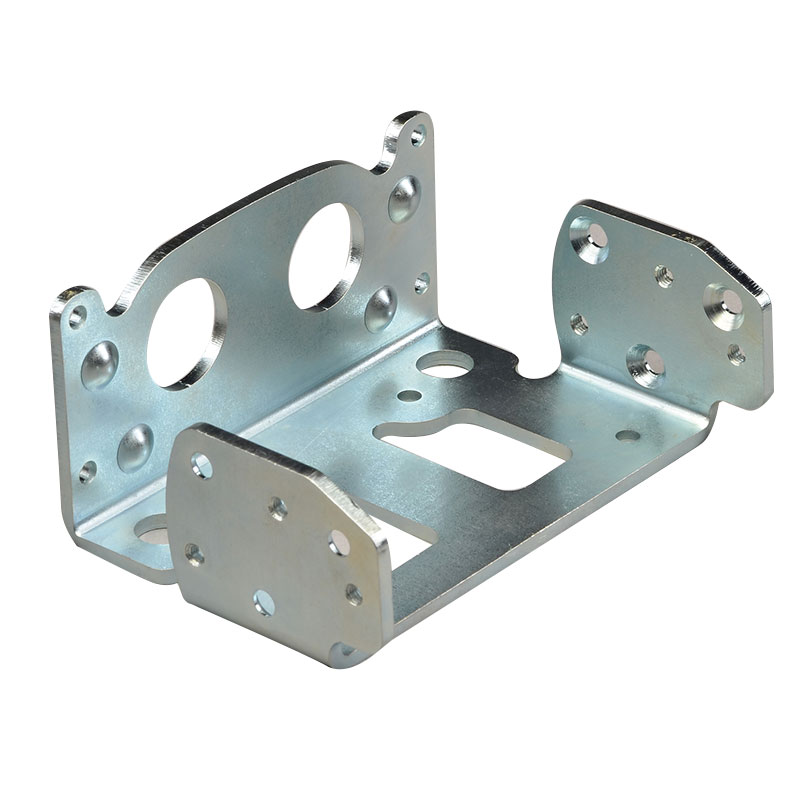

Hot Selling Low Price Precision Machined Sheet Bending Parts. Guoye Optoelectronics is Precision Machined Sheet Bending Parts manufacturer and supplier in China.Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.Aerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.