China Titanium Aerospace Components CNC Machining Manufacturers, Suppliers, Factory

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Titanium Aerospace Components CNC Machining,Titanium Aerospace Parts CNC Milling,Titanium Aerospace Products CNC Machining, Thanks for taking your useful time to go to us and look ahead to have a nice cooperation with you.

Titanium Aerospace Components CNC Machining, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

Hot Products

Auto Throttle Control Shafts Parts CNC Machining

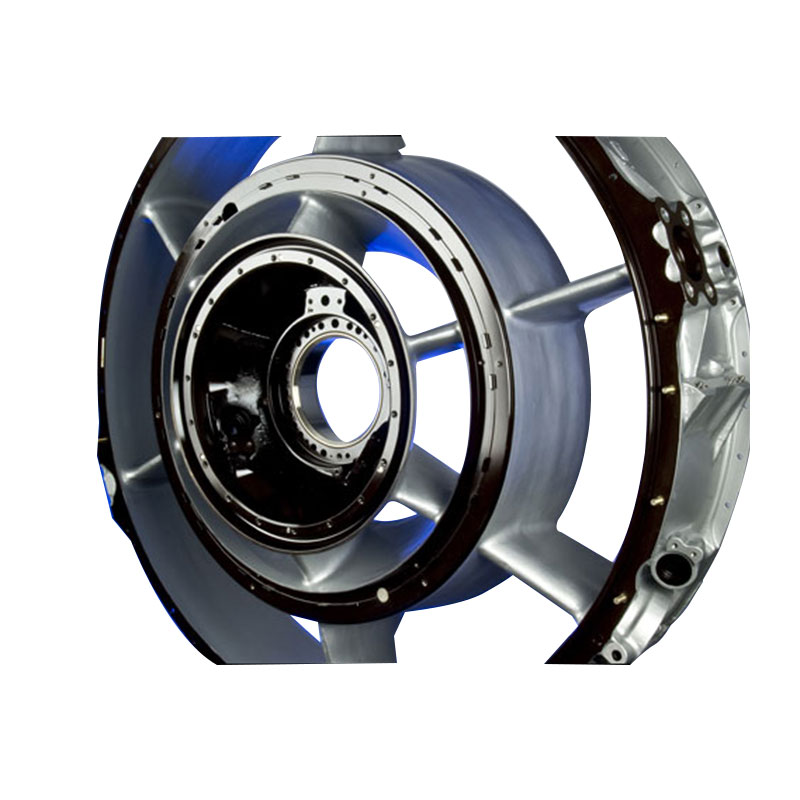

The following is about Auto Throttle Control Shafts Parts CNC Machining.Aluminium Mechanical CNC Machining Parts Anodizing

It's a CNC mill work for aluminium anodizing parts. After cnc machining is complete the part is anodized blue.

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through. Anodizing is a process for finishing aluminum alloys that employs electrolytic oxidation of the aluminum surface to produce a protective oxide coating. The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Conventional coatings are 0.1 to 1.0 mil thick and are essentially transparent but they may be colored like sample above.The following is about Aluminium Mechanical CNC Machining Parts Anodizing.Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Auto Sensor Housing Parts CNC Machining

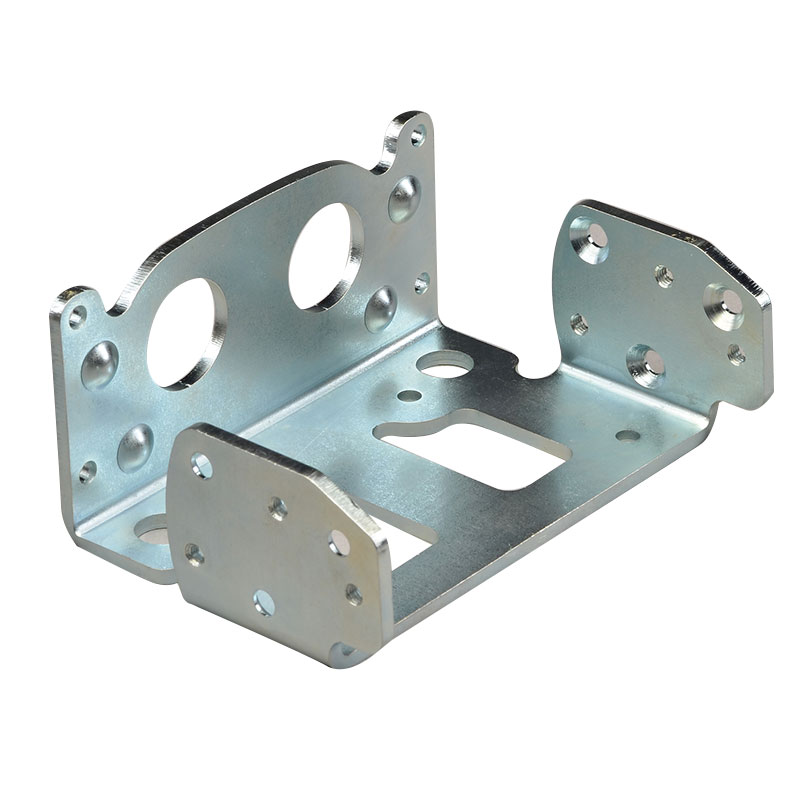

Because of the characteristics of high precision, high speed, high efficiency and safety and reliability, CNC turning parts are more and more widely used in equipment manufacturing industry, especially the automotive parts, which combines the latest technologies of automation, computer and measurement, and uses a variety of sensors to make it more flexible, versatile, reliable and easy to use and maintain.

The best Auto Sensor Housing Parts CNC Machining supplier ShenZhen Shbury technology Co.,Ltd provides custom CNC machined sensor housing parts. We are a popular manufacturer of all types of sensor housing made by high-quality precision CNC machining processing, especially the temperature sensor housing and pressure sensor housing.Office Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.Medical X-ray Housing Rapid Prototypes

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.