China Auto Throttle Control Shafts Components CNC Machining Manufacturers, Suppliers, Factory

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for Auto Throttle Control Shafts Components CNC Machining,Auto Throttle Control Shafts Parts CNC Milling,Auto Throttle Control Shafts Products CNC Machining,Auto Throttle Control Shafts Products CNC Machining, We adhere towards the tenet of "Services of Standardization, to fulfill Customers' Demands".

Auto Throttle Control Shafts Components CNC Machining, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality goods we offer you, effective and satisfying consultation service is supplied by our expert after-sale service group. Solution lists and detailed parameters and any other info weil be sent for you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been about to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Hot Products

Auto Transmission Parts CNC Turning

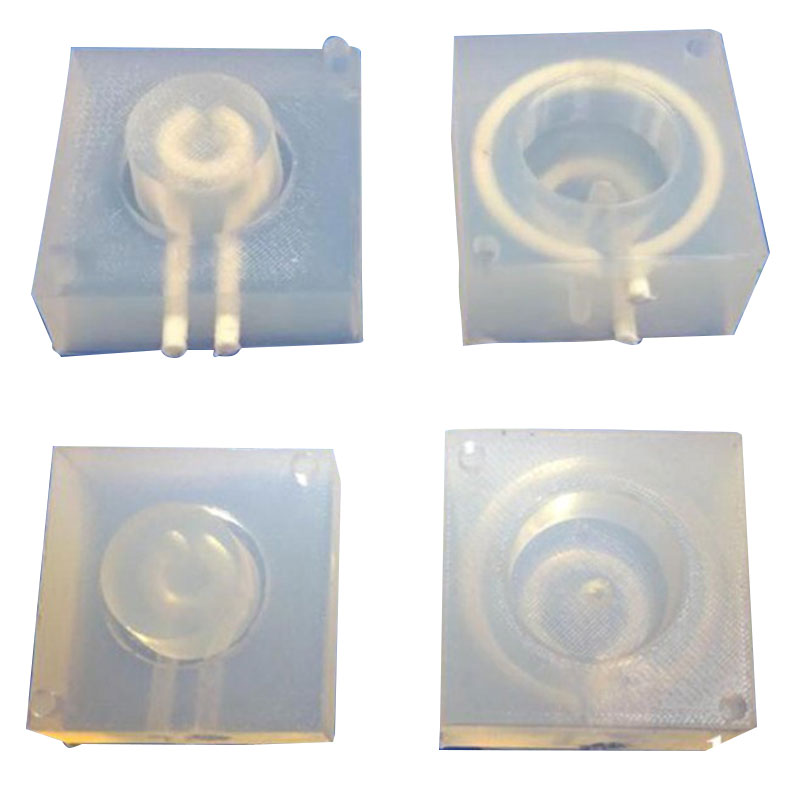

The following is about Auto Transmission Parts CNC Turning.Flexible Silicone Electronic Products Vacuum Casting

Urethane Casting - Silicone Molding Vacuum casting (also known as urethane casting or silicone moulding) is a manufacturing method that uses silicone moulds to produce plastic parts in a relatively simple way and without the high costs and high lead times required for steel or aluminium moulds.The following is about flexible silicone electronic products vacuum casting.Carbon Steel Military Parts CNC Turning

Shbury specializes in precision CNC parts and components that match military standards. We can provide complex machined parts at close tolerances along with accurate supporting documentation. The following is about Carbon Steel Military Parts CNC Turning.Electronic Drive Shaft Products CNC Turning

Eccentric shaft refers to the CNC Turning Part whose axis of the outer circle and the outer circle are parallel but not coincident, generally fixed on the rotating shaft of the motor through the eccentric hole. The recess pressure on the eccentric shaft is different, which caused circumferential flow. The CNC machining eccentric hollow shaft is different from the eccentric solid shaft, the diameter of the hollow shaft is more than the solid shaft and require more space. Hollow shafts have a more polar moment of inertia, thus they can transmit more torque compared to solid shafts.The following is about Electronic Drive Shaft Products CNC Turning.Titanium Aerospace Parts CNC Machining

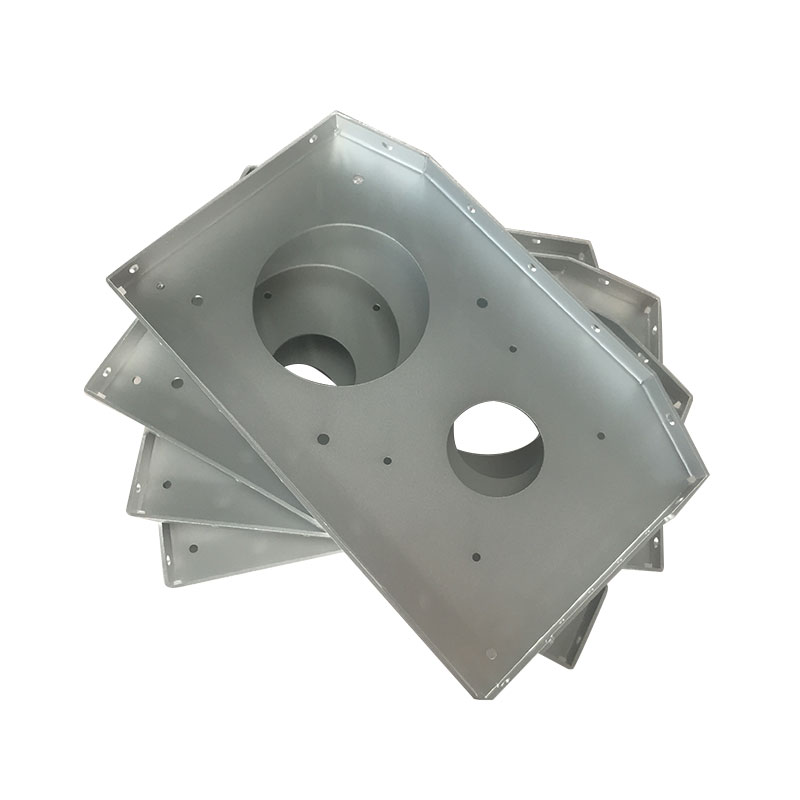

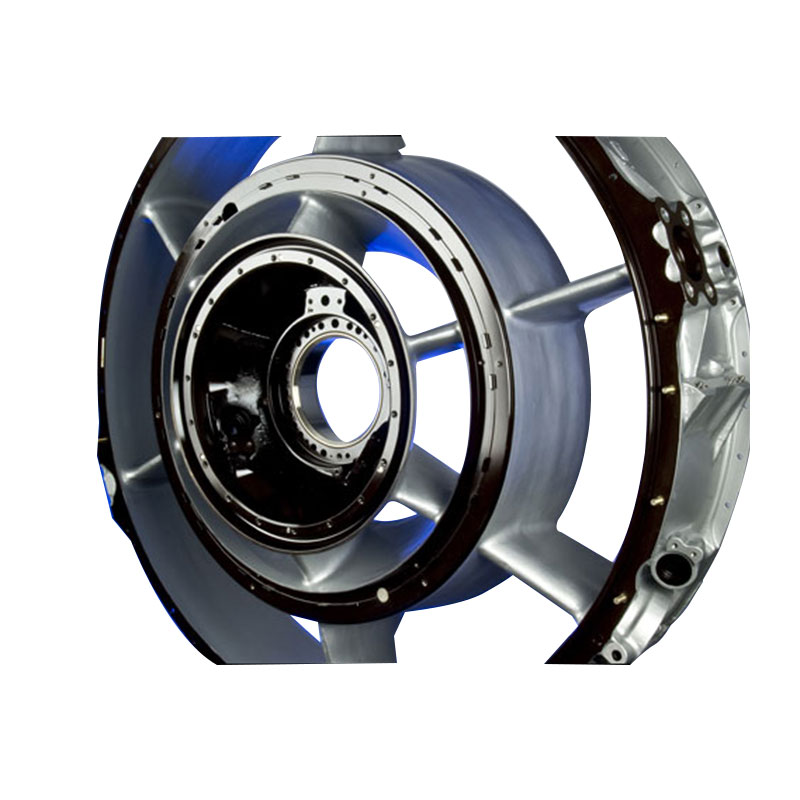

Our high volume components can withstand the intense pressures and various challenges of the Aerospace industry. Common components that we machine for the Aerospace industry include shafts, turbine disks, impellers, and more.The following is about titanium aerospace parts CNC machining.CNC Machining 4 axis Aluminium Anodizing Parts

CNC Machining 4 axis Aluminium Anodizing Parts:we are specialized manufacturers from China, Aluminum Block, Cnc Milling Machining Parts suppliers/factory, wholesale high-quality products of Aluminum Cnc Machining Parts R & D and manufacturing, we have the perfect after-sales service and technical support. Look forward to your cooperation!