China Auto Throttle Control Shafts Parts CNC Milling Manufacturers, Suppliers, Factory

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for Auto Throttle Control Shafts Parts CNC Milling,Auto Throttle Control Shafts Products CNC Machining,Auto Throttle Control Shafts Components CNC Machining,Auto Throttle Control Shafts Products CNC Machining,Auto Throttle Control Shafts Components CNC Machining, Safety by innovation is our promise to each other.

Auto Throttle Control Shafts Parts CNC Milling, Welcome to visit our company, factory and our showroom where displays various hair solutions that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Be sure to contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Hot Products

Auto Sensor Housing Parts CNC Machining

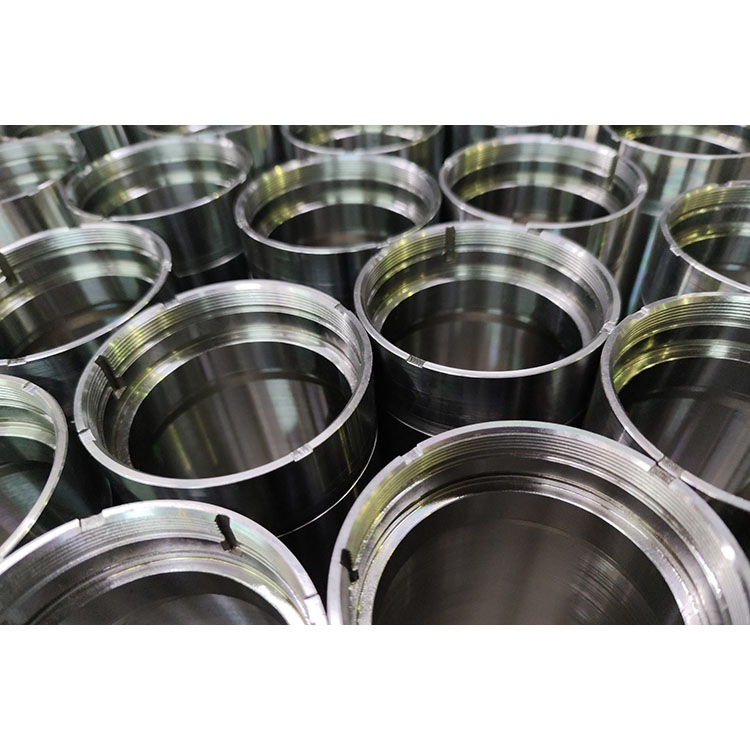

Because of the characteristics of high precision, high speed, high efficiency and safety and reliability, CNC turning parts are more and more widely used in equipment manufacturing industry, especially the automotive parts, which combines the latest technologies of automation, computer and measurement, and uses a variety of sensors to make it more flexible, versatile, reliable and easy to use and maintain.

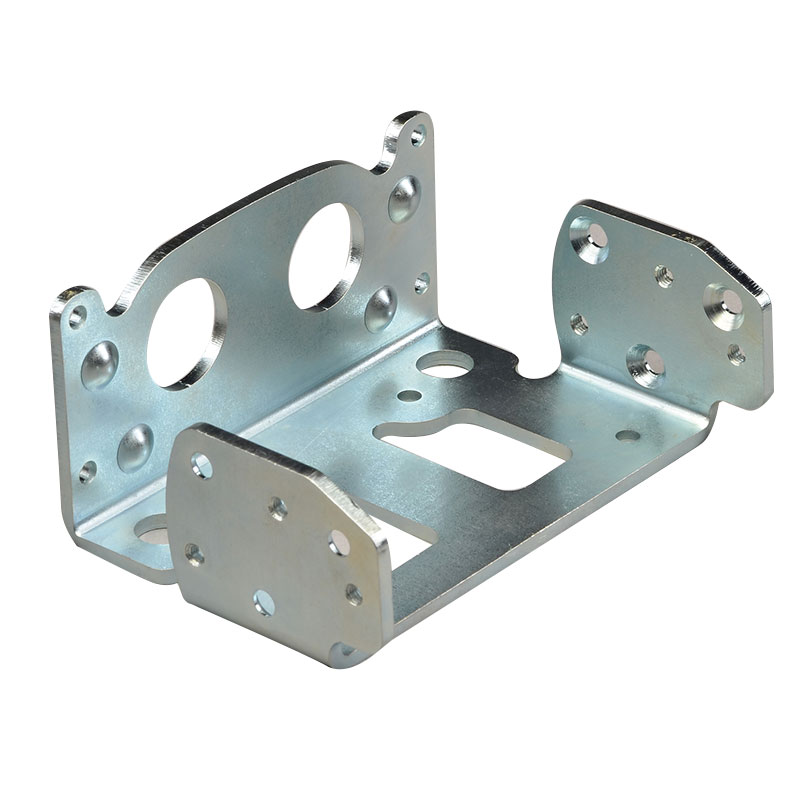

The best Auto Sensor Housing Parts CNC Machining supplier ShenZhen Shbury technology Co.,Ltd provides custom CNC machined sensor housing parts. We are a popular manufacturer of all types of sensor housing made by high-quality precision CNC machining processing, especially the temperature sensor housing and pressure sensor housing.Sheet Metal Stamping Precision Stamping Parts

Hot sale quality Sheet Metal Stamping Precision Stamping Parts with Low Price made in China. Guoye Optoelectronics is Sheet Metal Stamping Precision Stamping Parts manufacturer and supplier in China.Medical Glucose Meter Device Rapid Prototypes

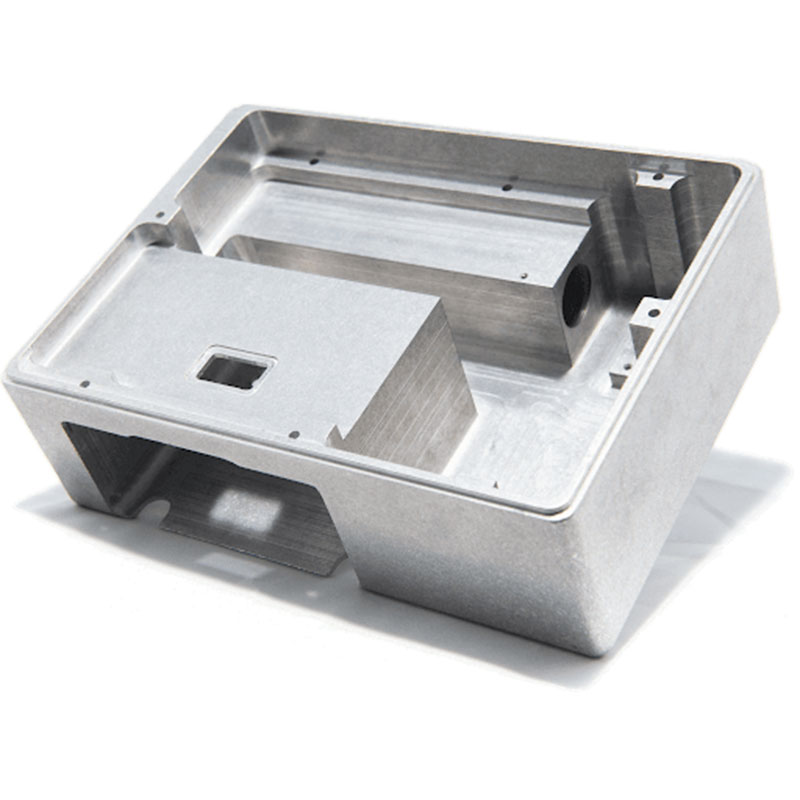

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.Auto Flanges Fuser Rollers Parts CNC Turning

With the aid of our diligent professionals, we are engaged in manufacturing and supplying Turning Flange. These flanges are available for the clients in different sizes and specification. Precision turned from raw metal using high-end cnc machines, these flanges are provided to a large number of customers ranging from engineering to automotive industries Our offered flanges are quality tested with the aid of diligent analysts before the final dispatch. The Turning Flange is provided at the specified place on time.The following is about Auto Flanges Fuser Rollers Parts CNC Turning.Auto Waterproof Rubber Parts Vacuum Casting

We frequently vacuum cast rubber auto waterproof parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre (Shore 30 – 95A hardness) The level of detail matches that of an injection moulded part.The following is about Auto Waterproof Rubber Parts Vacuum Casting.Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.