China Auto Throttle Control Shafts Products CNC Machining Manufacturers, Suppliers, Factory

Every single member from our large efficiency profits team values customers' requirements and organization communication for Auto Throttle Control Shafts Products CNC Machining,Auto Throttle Control Shafts Parts CNC Milling,Auto Throttle Control Shafts Components CNC Machining,Auto Throttle Control Shafts Components CNC Machining, In case you have any comments about our company or products and solutions, make sure you feel free of charge to speak to us, your coming mail might be highly appreciated.

Auto Throttle Control Shafts Products CNC Machining, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

Hot Products

OEM Precision CNC Machining aluminium Anodizing Spare Parts

OEM Precision CNC Machining aluminium Anodizing Spare Parts:Before we look into aluminum parts anodizing, we should understand the exact meaning and purpose of anodizing. Generally, anodizing is a process through which a layer of metal oxide is electrolytically embedded onto the surface of the pure metal, in this case, Aluminum pars anodizing is like painting but when anodizing, the oxide layer is fully integrated into the underlying metal. Because of this, it can hardly chip or peel. Anodizing is the result of a highly controlled oxidation process that converts the surface of the metal into a corrosion-resistant, durable cover.Auto Sensor Housing Parts CNC Machining

Because of the characteristics of high precision, high speed, high efficiency and safety and reliability, CNC turning parts are more and more widely used in equipment manufacturing industry, especially the automotive parts, which combines the latest technologies of automation, computer and measurement, and uses a variety of sensors to make it more flexible, versatile, reliable and easy to use and maintain.

The best Auto Sensor Housing Parts CNC Machining supplier ShenZhen Shbury technology Co.,Ltd provides custom CNC machined sensor housing parts. We are a popular manufacturer of all types of sensor housing made by high-quality precision CNC machining processing, especially the temperature sensor housing and pressure sensor housing.Auminium Sheet Metal Stamping Parts

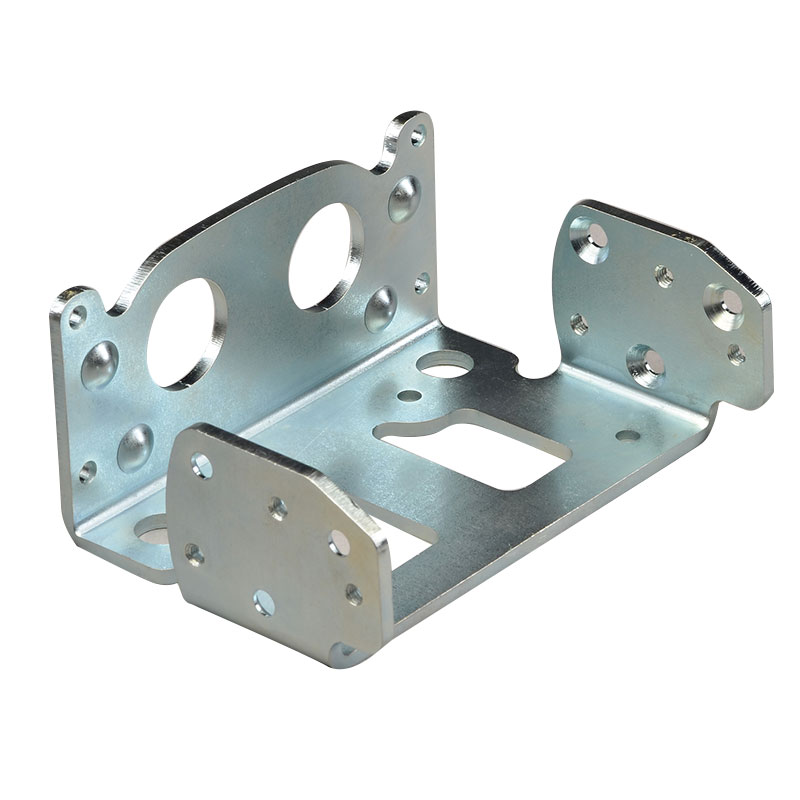

Take your custom products to the next level with high-grade aluminum sheet metal stampings parts from Shbury. We’re an aluminum stamping factory that will support your vision by providing custom aluminum parts tailored to your unique project. Thanks to our industry-leading in-house tooling capabilities and favorable lead times, you can trust that we will deliver on time and on budget.

At Shbury we don’t take a cookie-cutter approach to any of our partnerships. Our tooling is completely customized and we’re able to meet your exact manufacturing needs through extensive list of value added services.The following is about auminium sheet metal stamping parts.Vacuum Casting Prototype for Mobile Phone Housing

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Smart Mechanical Parts Vacuum Casting

Vacuum casting services is a type of rapid prototyping technology. It is used for producing a photocopy of the original product in a vacuum state, and then use (PU, transparent PU, POM-like, ABS) and other materials to cast the same copy as the product prototype.

Vacuum casting services are suitable for the customer who requires several sets of rapid prototype parts, which significantly reduces the cost and development time. The following is about Smart Mechanical Parts Vacuum Casting.