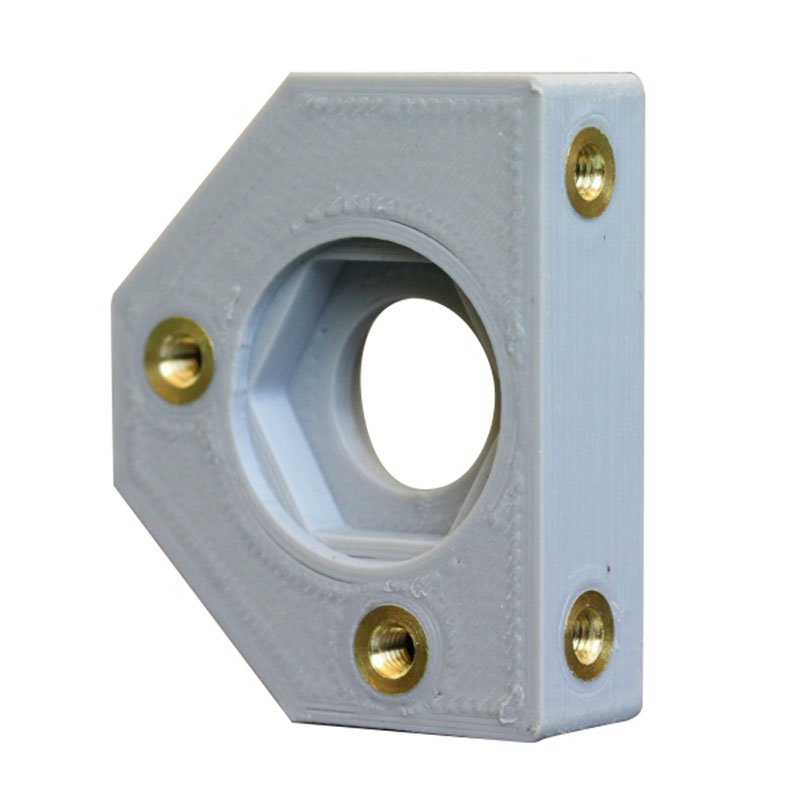

China Plug Inserts with Hollow Brass Pins Plastic Manufacturers, Suppliers, Factory

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for Plug Inserts with Hollow Brass Pins Plastic,Polishing Cast Bronze Brass Copper Casting,Pipe Fittings PVC Elbow Inserts Brass,Precision Injection Molding Brass Inserts Nut,Electrical Brass Fuse Cutout Parts, With our rules of " small business track record, partner trust and mutual benefit", welcome all of you to definitely work together , expand with each other.

Plug Inserts with Hollow Brass Pins Plastic, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we've got established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our solutions, and we're sure that we are going to offer just what you want, as we always believe that your satisfaction is our success.

Hot Products

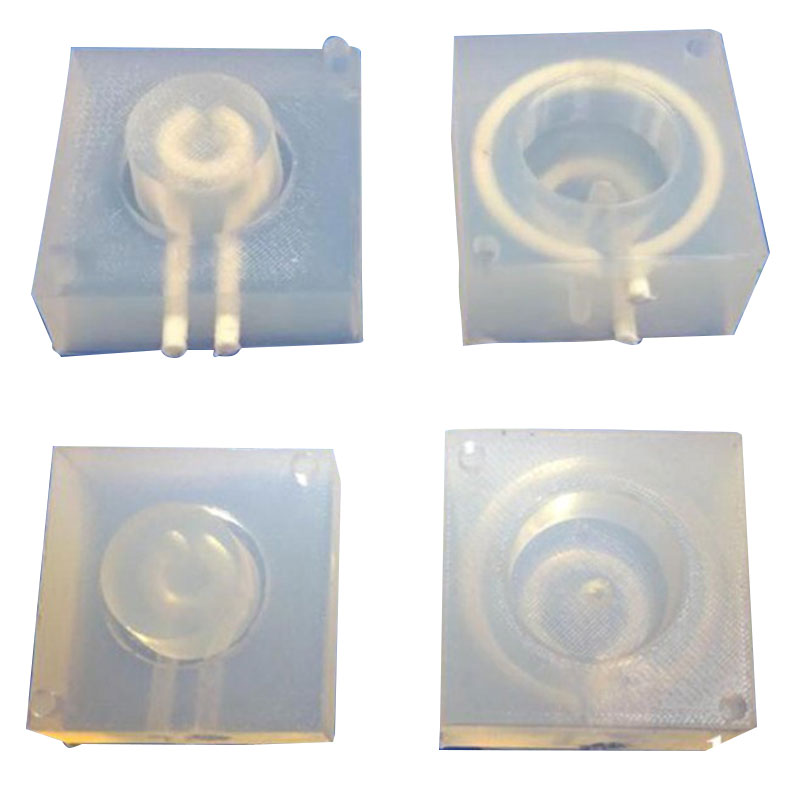

Aerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.Carbon Steel Military Parts CNC Turning

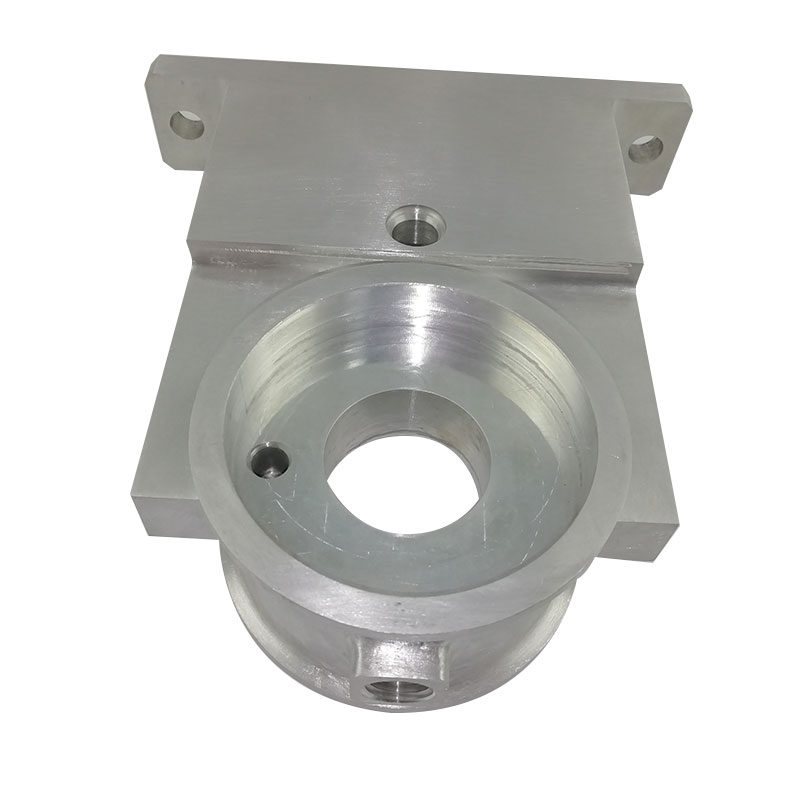

Shbury specializes in precision CNC parts and components that match military standards. We can provide complex machined parts at close tolerances along with accurate supporting documentation. The following is about Carbon Steel Military Parts CNC Turning.Dental Instruments Parts CNC Machining

The following is about Dental Instruments Parts CNC Machining.Auto Parts Heat Treatment Rapid Prototypes

Heat treatments can be applied to metal alloys throughout the manufacturing process. For CNC machined parts, heat treatments are typically applied either:

Before CNC machining: When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining: Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.The following is about Auto Parts Heat Treatment Rapid Prototypes.Silicone Buttons Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal. But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about silicone buttons products vacuum casting.Vacuum Casting Prototype for Mobile Phone Housing

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.