China Auto Pipe Joint Components CNC Machining Manufacturers, Suppliers, Factory

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Auto Pipe Joint Components CNC Machining,Auto Pipe Joint Parts CNC Milling,Auto Pipe Joint Products CNC Machining, "Quality first, Price lowest, Service best" is the spirit of our company. We sincerely welcome you to visit our company and negotiate mutual business!

Auto Pipe Joint Components CNC Machining, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our solutions and the processes to fulfill your needs.

Hot Products

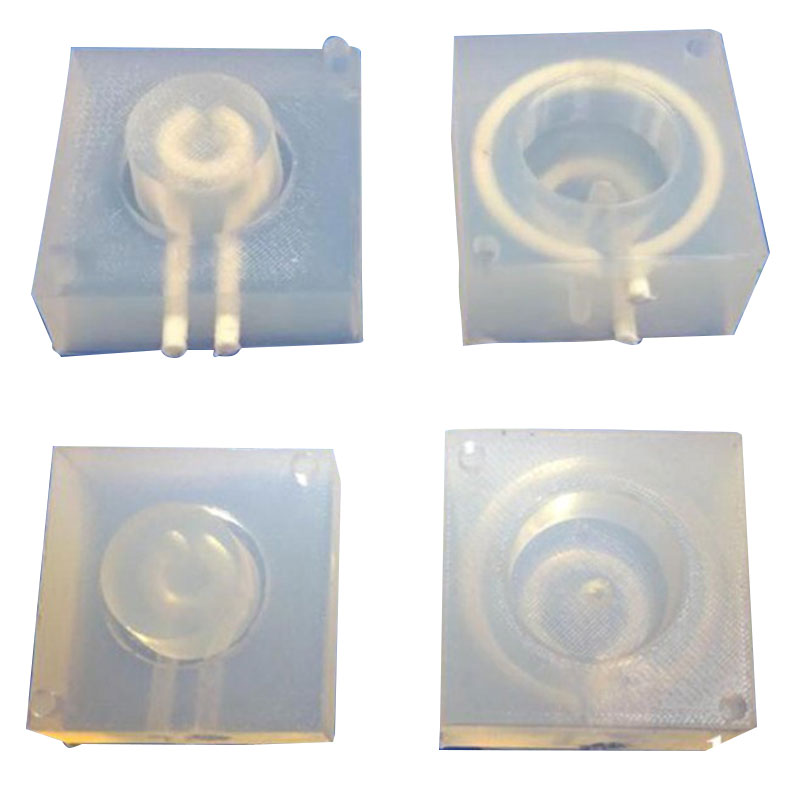

Aerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.Electronic Bushes Products CNC Turning

The following is about Electronic Bushes Products CNC Turning.Military Parts Dowel Pins CNC Turning

We carefully consider the dowel pins material to be used as well as the dowel destination. We take into account the ductility of the destination hole and the ductility of the dowel pins material being used to manufacture the machined parts with accurate dimensions. Regarding size and precision, Alpha Omega Swiss manufactures precision dowel pins to exacting tolerances. We can produce dowel pins to a tolerance of +/- .0001 utilizing stainless steel, tool steel, brass, or aluminum.The following is about Military Parts Dowel Pins CNC Turning.Auto Parts Heat Treatment Rapid Prototypes

Heat treatments can be applied to metal alloys throughout the manufacturing process. For CNC machined parts, heat treatments are typically applied either:

Before CNC machining: When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining: Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.The following is about Auto Parts Heat Treatment Rapid Prototypes.Robotic Mechanical Parts CNC Machining

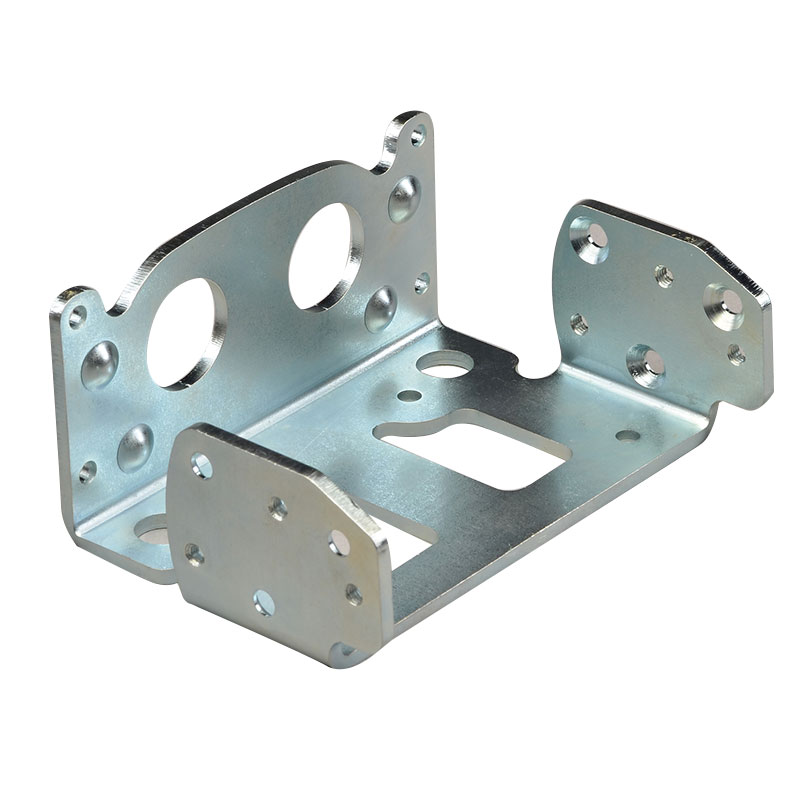

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about robotic mechanical parts CNC machining.Mechanical Connectors Parts CNC Turning

Mechanical Connectors Parts, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.The following is about Mechanical Connectors Parts CNC Turning.