China ACNC Machining Parts Manufacturers, Suppliers, Factory

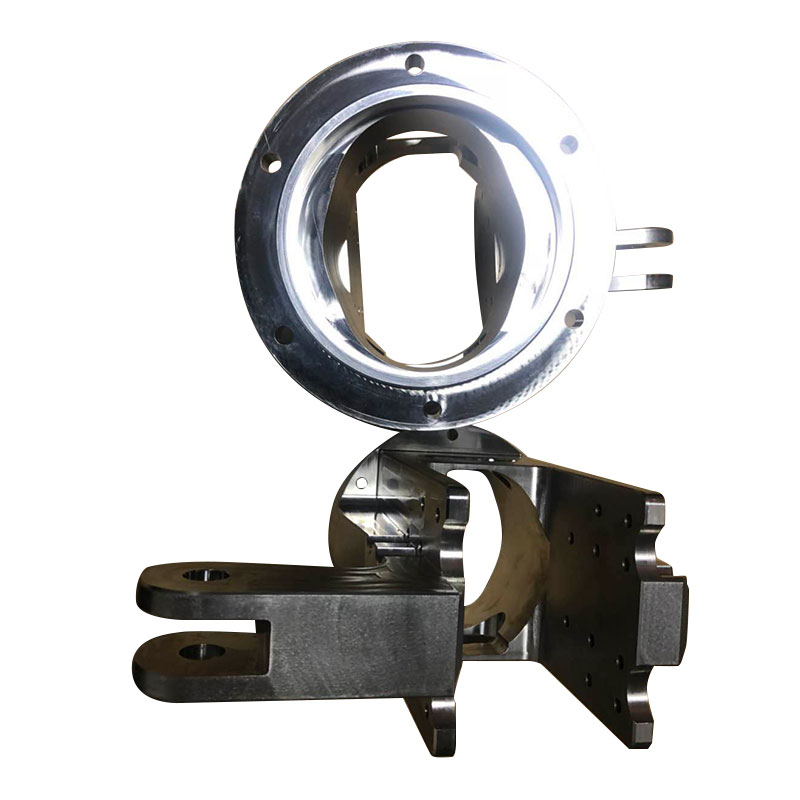

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for ACNC Machining Parts,Brass Aerospace Parts CNC Milling,Brass Aerospace Products CNC Machining,Brass Aerospace Components CNC Machining,OEM CNC Machining Parts for Aerospace Field, Only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment.

ACNC Machining Parts, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to offer the high-quality products and solutions and services, and promote lasting cooperation with our customers, common development and create a better future.

Hot Products

Electronic Hookah Nozzle Products CNC Turning

The following is about Electronic Hookah Nozzle Products CNC Turning.Auto Oil And Gas Rubber Parts Vacuum Casting

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Cold Rolled Steel Sheet Metal Parts

Cold Rolled Steel Sheet Metal Parts have been available for many, many years, and have been successfully used for a multitude of applications. Today's Cold Rolled Steel Sheet Metal Parts are much improved over those used in the past. They offer better control of thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly engineered end use applications.Mechanical Connectors Parts CNC Turning

Mechanical Connectors Parts, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.The following is about Mechanical Connectors Parts CNC Turning.PEEK Auto Parts Rapid Prototyping

The following is about PEEK Auto Parts Rapid Prototyping.