China Sheet Metal Stamping-Metal Parts Manufacturers, Suppliers, Factory

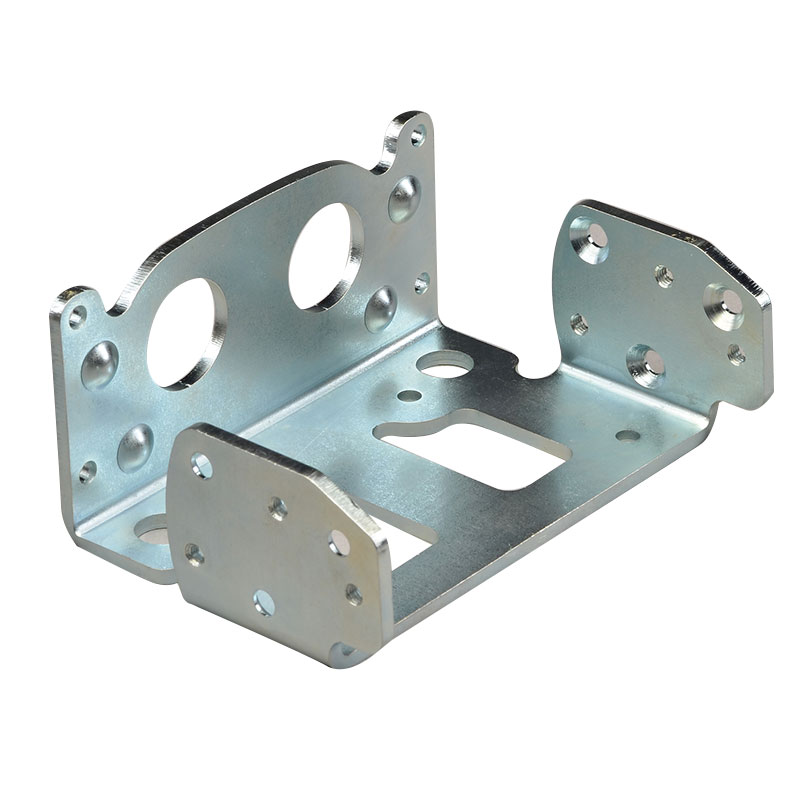

Our pros are reduce price ranges,dynamic gross sales staff,specialized QC,potent factories,premium quality services for Sheet Metal Stamping-Metal Parts,Sheet Stamping Small Metal Parts,Sheet Metal Stamping Parts,Metal Stamping Sheet Metal Parts,Metal Sheet Aluminum Stamping Parts, We welcome all with the consumers and pals to call us for mutual positive aspects. Hope to do additional company along with you.

Sheet Metal Stamping-Metal Parts, All styles appear on our website are for customizing. We meet up to individual requirements with all solutions of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Hot Products

Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.Electronic Drive Shaft Products CNC Turning

Eccentric shaft refers to the CNC Turning Part whose axis of the outer circle and the outer circle are parallel but not coincident, generally fixed on the rotating shaft of the motor through the eccentric hole. The recess pressure on the eccentric shaft is different, which caused circumferential flow. The CNC machining eccentric hollow shaft is different from the eccentric solid shaft, the diameter of the hollow shaft is more than the solid shaft and require more space. Hollow shafts have a more polar moment of inertia, thus they can transmit more torque compared to solid shafts.The following is about Electronic Drive Shaft Products CNC Turning.Flexible Silicone Electronic Products Vacuum Casting

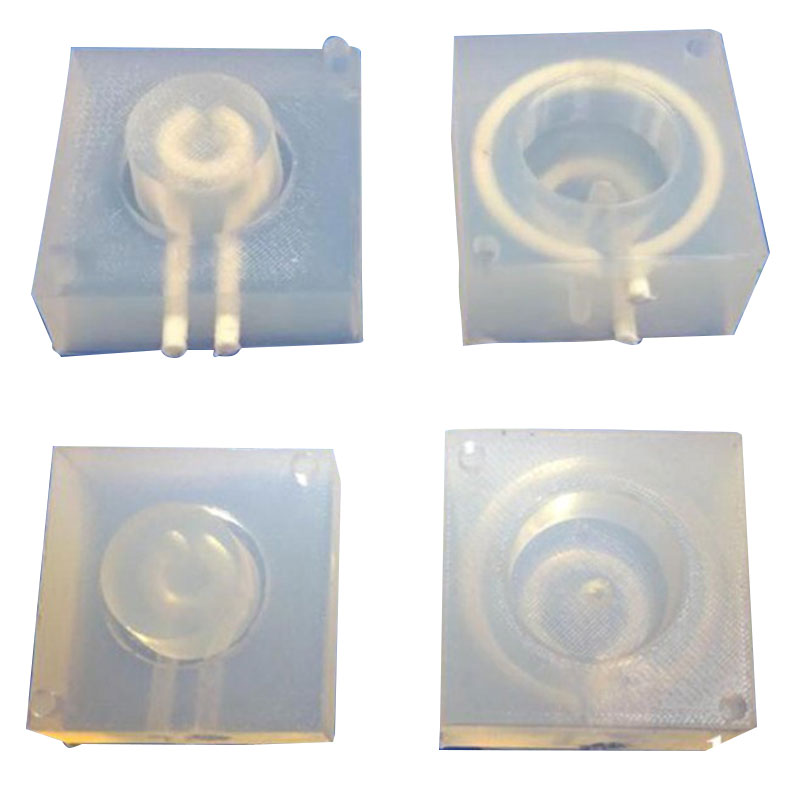

Urethane Casting - Silicone Molding Vacuum casting (also known as urethane casting or silicone moulding) is a manufacturing method that uses silicone moulds to produce plastic parts in a relatively simple way and without the high costs and high lead times required for steel or aluminium moulds.The following is about flexible silicone electronic products vacuum casting.Aerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy